General Properties:

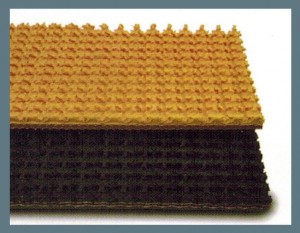

Rough top belting has been the preferred solution for incline/decline conveying for many years. We offer a wide range of plied rubber roughtop belting ranging from our cost effective Grade II SBR, Tan non-marking Grade II SBR, Pure Gum for steep incline/decline applications, and our highly abrasion resistant Carboxylated Nitrile (XNBR). Each product has been engineered to the highest quality standards and to offer the optimum in performance and value in each application.

All of our rough top belting is produced on high quality RFL treated Polyester/Nylon fabric, The polyester warp offers high strength and low stretch while the nylon fill offers excellent fastener retention properties as well as greater resistance to shock-loading.

Typical Applications:

Black Grade II SBR Rough tops:

- Economical operation in high volume incline applications where competition is tough.

- General Incline/decline conveying up to 35%

- Airports/Logistics/Distribution Centers

- Automotive parts conveying

- Light-duty Industrial

- Agriculture

Tan (non-marking) Grade II SBR Rough tops:

- Similar to black Grade II except non-marking

- Cardboard box conveying

Tan Pure Gum Rough tops:

- Able to handle steep inclines/declines up to 45%

- Pure Gum Natural Rubber formulation offers exceptional wear, up to 2 times the wear of SBR.

- Paper Industry

Carboxylated Nitrile (XNBR) Rough tops:

- Carboxylated Nitrile (XNBR) rubber formulation offers the highest abrasion resistance in the industry, up to 3 times the wear of SBR.

- XNBR compound offers excellent oil resistance

- Extended belt life reduces downtime and costs associated with more frequent belt replacement

- Corrugated Boxboard Industry

- Paper Industry

- Automotive where long belt life, resistance to abrasion, and oil resistance are needed

- Forest Products including plywood and lumber

Comments are closed.